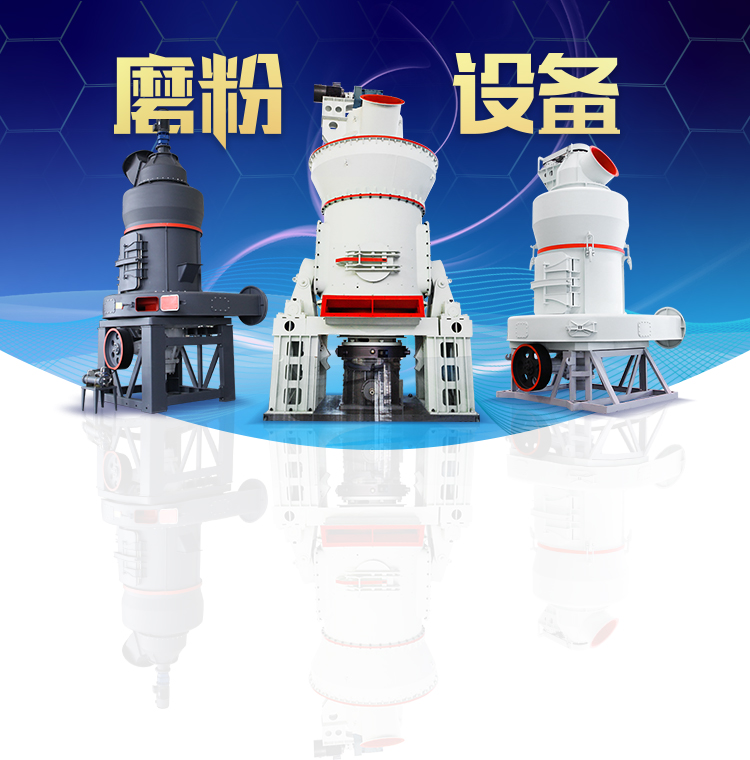

细粉加工设备(20-400目)

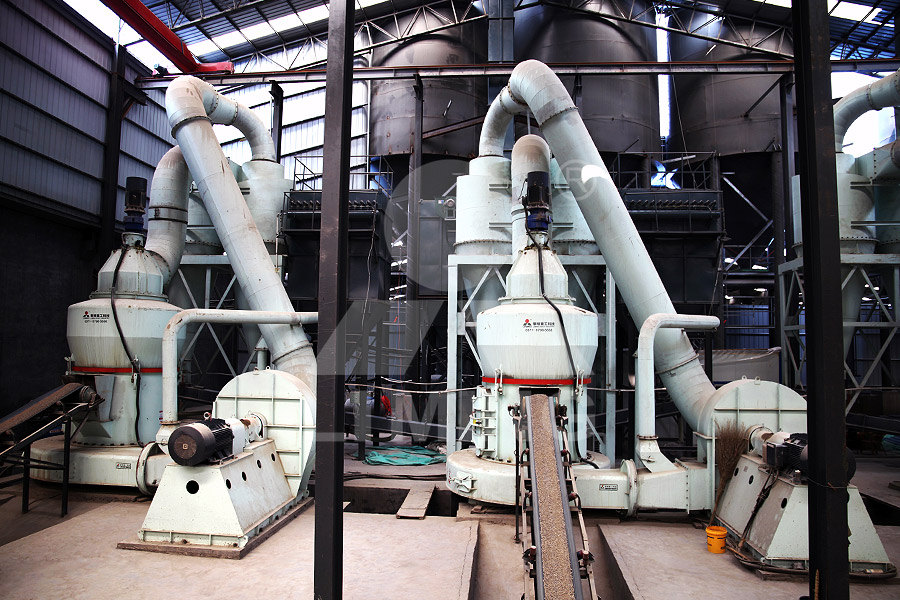

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

iron grinding mill

Iron Ore Processing: From Extraction to

2024年4月26日 Grinding Mills: Grinding mills, such as ball mills and rod mills, are commonly used for grinding iron ore These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into 2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral 2022年1月1日 To operate viably and sustainably, there is a need to reduce costs and energy consumption, particularly of the energyintensive grinding required for lowgrade magnetite Comminution and classification technologies of iron ore2015年3月15日 Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test Research of iron ore grinding in a verticalrollermill

The six main steps of iron ore processing Multotec

The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or Grinding within a tumbling mill is influenced by the size, quantity, the type of motion, and the spaces between the individual pieces of the medium in the mill As opposed to crushing, which Grinding Mill an overview ScienceDirect Topics2024年5月6日 The STM vertical stirred grinding mill can be used for coarse, fine and ultrafine grinding applications, while adding flexibility in flowsheet design and process development Coarse particle processing has the potential to help NRRI advances efficient grinding technology on 2020年3月28日 Modern iron ore pelletizing process operations may be divided into two main process sections: feedstock preparation and agglomeration processes In most plants, the Development of a Novel Grinding Process to Iron Ore

uses of iron oreiron ore grinding milliron ore Raymond mill

For iron ore powder, Raymond mill can produce 80400 mesh, vertical mill can produce 325 mesh, and ultrafine vertical mill can produce 3252500 mesh4 天之前 Stirred milling was developed for fine grained ores that required an economic grind to sub 10 micron sizes The first examples were lead zinc deposits – McArthur River, George Fine Grinding as Enabling Technology – The IsaMill2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in ball mills(PDF) Grinding Media in Ball MillsA Review ResearchGate4 天之前 Isa Mill (2 mm sand) (for KCGM pyrite concentrate) Chemistry Impacts The use of inert grinding media gives a crucial advantage to stirred milling in fine flotation and leaching applications Even if it were economic to grind to 10 microns in a steel mill with very small balls, the amount of iron in solution would almost certainly ruin downstreamFine Grinding as Enabling Technology – The IsaMill

Balls, iron/steel, forged/stamped for grinding mills

In 2022, Balls, iron/steel, forged/stamped for grinding mills were the world's 1664th most traded product, with a total trade of $167B Between 2021 and 2022 the exports of Balls, iron/steel, forged/stamped for grinding mills grew by 259%, from $133B to $167B Trade in Balls, iron/steel, forged/stamped for grinding mills represent 00071% 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral 2023年11月24日 Cast iron grinding media are one of the ancient media, which were first used in mineral processing and can be grouped into cast lowchrome and highchrome white iron The cast irons are heattreated to adjust the amount of retained austenite and vary the carbide size and distribution, resulting in a microstructure with superior hardness and Grinding Media in Ball Mills for Mineral Processing2024年3月19日 This grain mill is a large grinder with a 2lb hopper to ground a good amount of flour The grinder is aluminum cast and resistant to rust corrosion In addition, there are two ball bearings for the specific grinding instead of bushings used by other manufacturers The grinder offers an adjustable level of how fine flour you want5 Best Manual Grain Mills For Freshly Ground Flour Build a

Corona Corn Grinder with High Hopper, Grain Mill, Manual Grinder

2022年5月26日 About this item Cast Iron Corn and Grain Mill: The traditional Corona corn and grain mill has a complete cast iron body with a high hopper Sturdy, heavyduty, and durable to last a lifetime2022年8月26日 Then you need a cast iron spice grinder, stat! We reviewed six of the best pepper grinder options and highlighted a few other elements to streamline your choice Table of Contents The 6 Best Cast Iron Spice Grinders However, most people were quite optimistic about this cast iron spice mill and found it was an excellent option for their 7 Best Cast Iron Spice Grinders TastyliciousGrinding The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or screening after milling, which decreases the kWhr per ton ground When the material exits the mill, the iron ore is classified using The six main steps of iron ore processing MultotecGrinding is much easier and more fun with two people Bushing/sealed bearings eliminate maintenance never need to be oiled! Built to last This mill hearkens to an earlier time when things were built to outlast their owner and be passed on to the next generation Solid cast iron mill is one of the heaviest hand mills in the worldDiamant CastIron Manual Grain Mill Extreme Wellness

.jpg)

Iron ore grinding mill Grinding plants for Iron Ore

Phrase one: raw material crushing Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder Phrase three: classifying Ground material will be classified, coarse powder will fall back to the main mill for ground again3 天之前 How to Assemble and use a Victoria Cast Iron Grain Grinder Mill 9 Cast Iron Crank Manual Grain Mill Buy on Amazon This grain miller is very sturdy, and it can grind any seeds or seeds you want very fine The fine level 15 Best Manual Grain Mills or Ginders in 年1月13日 Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in Grinding Media in Ball MillsA Review ResearchGate2024年6月19日 The F4 grinding mill head can be easily disassembled for cleaning without the use of any special tools The grinding plates are made of a hard iron alloy designed for clog resistance and long life A new optional acicular iron grinding plate has now been introduced as an offering, a stronger plate that “work hardens” as the grinding plates Model 4F Hand Mill Quaker City Grinding Mills QCG Sys

.jpg)

Research of iron ore grinding in a verticalrollermill

4 天之前 One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here Within these test works, mill parameters like grinding pressure, separator speed and dam ring height were varied, following a factorial design of the experiments2023年5月2日 The mill comes with a limited lifetime warranty from Victoria, covering craftsmanship defects for life from the date of purchase The Victoria is an economical hand mill best suited for grinding dry grains and legumes into coarse meal and flour, but it won’t produce fine pastry flour Home brewers love it for grinding barley malt, as well!The Best Countertop Grain Mills and Flour Grinders in 2023 Foodal2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which Friction and wear of liner and grinding ball in iron ore ball mill High Hardness 20mm 25mm 30mm 40mm 60mm 80mm Steel Ball Casting Iron Ore Grinding Media Ball for Ball Mill Machine Factory US$5500069000 20 Tons (MOQ) Ball Mill Steel Cylpebs Quality High Chrome Casting Grinding Media Grinding Material Ltd is a professional manufacturer and exporter of grinding mill ball in China It is located in Grinding Ball Manufacturer, Steel Ball, Grinding Media Ball

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) The produced 2022年7月12日 grinding mill at Miaogou Iron Mine to achieve the goal of the technological transformation and smoothly riding out the current market’s difficulties Results Now with Vertimills in place, the grinding circuit sees an increase in grinding fineness from 7173% to 8890% passing 325 mesh, increase from 65% to 66% inStirred mills Metso2024年5月16日 Cast iron grinding balls – grinding media with the geometric shape of a ball and produced by casting molten iron into special forms (sand moulds or chill moulds) Energosteel at XXІ INTERNATIONAL ENERGY Cast iron grinding balls Energosteel Grinding 2024年5月6日 A crucial step in mineral processing – and in Minnesota’s iron ore processing – is comminution, a process of crushing and grinding Large rocks must first be crushed and then ground down to tiny particles to expose the NRRI advances efficient grinding technology on

.jpg)

Victoria Cast Iron Tinned Grain Grinder/Corn Mill

Weight 10 LBS Dimensions 52 x 61 x 125 in Give your cooking the upgrade it deserves with highquality castiron cookware Castiron cookware is superior to traditional cookware because it outlasts more conventional kitchen cookware 2013年8月1日 Likewise, Hebbar (2011) has studied the grinding wear behaviour of austempered ductile iron as media material in the comminution of Kudremukh haematite iron ore in a ball mill The grinding experiments were conducted under different pH conditions, ie pH = 70 and pH = 85, while keeping other parameters fixed, at a mill speed of 74 rpm for 1 hrConsumption of steel grinding media in mills – A review2014年1月1日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection Population balance model approach to ball mill optimization in iron DOI: 101016/JPOWTEC202107030 Corpus ID: ; Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills @article{Carvalho2021MechanisticMA, title={Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills}, author={Rodrigo M de Carvalho and Mechanistic modeling and simulation of grinding iron ore

.jpg)

Corona Cast Iron Corn and Grain Mill with Wooden Table, Corn Grinder

Amazon: Corona Cast Iron Corn and Grain Mill with Wooden Table, Corn Grinder, Grain Mill, Manual Grinder with Table For Corn, Rice, Lentils, Chickpeas, Cast Iron Grinder For Domestic Use, AntiRust By Corona : Home KitchenThe group company consists of Jinan Huafu Forging Co,Ltd,Shandong Huafu Steel Ball Co,Ltd and Jinan Xing Tigers of Papermaking Machinery Co,LtdWe mainly produces forged steel balls, cast iron balls, steel cylpebs, grinding rods, mill liners, steel, hammer heads, automatic production lines for steel balls grinding rods, decorative wrought Jinan Huafu Forging JointStock Co, Ltd2022年1月1日 The mill is filled with suitable grinding media, and the space between each of the disks is essentially an individual grinding chamber As a result, the mill effectively comprises eight grinding chambers in series The media is set in motion by the action of the grinding disks, which accelerate the media nearby radially toward the minution and classification technologies of iron ore2021年11月1日 The present work analyzes the application of the UFRJ mechanistic ball mill model to grinding of iron ore pellet feed in an industrial grinding circuit In order to address the challenge of applying the model to a reasonably fine feed, selected model parameters were backcalculated on the basis of batch grinding tests The model is then used to Mechanistic modeling and simulation of grinding iron ore

.jpg)

Helping to reduce mining industry carbon emissions: A step

2022年3月30日 Currently Autogenous (AG)/SemiAutogenous (SAG)/Ball mill technology dominates comminution circuit design where grinding to relatively fine sizes is required, eg the gold, copper, nickel, platinum, silver, lead, zinc and low grade iron ore sectors2015年4月9日 Very fine grinding mills The following are the mills used for very fine grinding Hammer mills Hammer mills are high speed mills operating at speeds of between 2000 rpm and 6000 rpm A set of ‘hammers’ rotate about a Grinding Mills and Their Types IspatGuru2024年10月15日 High costeffectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills Grinding Mills Mineral Processing EquipmentFor iron ore powder, Raymond mill can produce 80400 mesh, vertical mill can produce 325 mesh, and ultrafine vertical mill can produce 3252500 mesh Toggle navigation so on Iron exists in nature in the form of compounds, and natural iron ore can be gradually selected after crushing, grinding, magnetic separation, flotation and gravity uses of iron oreiron ore grinding milliron ore Raymond mill

How it Works: Crushers, Grinding Mills and Pulverizers

2017年6月2日 Grinding Mills and Pulverizers Grinding mills and pulverizers are the second level of material reduction equipment after crushers Mills and pulverizers transform materials through pressure or blades to grind, cut or crush it As there is with crushers, there are many different types of grinding mills and pulverizers availableOur Laboratory Grinding Mill comes standard with a 1 HP motor and optional variable speed drive ranging from 1 to 100 RPM wheel speed of 14 rpm The stamps, 6½ by 7½ in by 14 ft in dimensions, weigh 450 to 500 lb including the castiron shoe The mills are usually built with three stamps to the mortar box and as many as three sets FLOOR MOUNTED LABORATORY GRINDING MILL2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral 2024年10月27日 DOVE offers a wide range of high quality ball mills, for wet or dry grinding operations, as well as regrinding application, for capacities up to 240 Tons/Hour DOVE supplies Steel Balls in Various sizes and specifications Cast Iron steel Balls, Forged grinding steel balls, Glaze Ball, High Chrome cast steel bars, with hardness of 6068 HRCBall Mill Ball Mills Wet Dry Grinding DOVE

Research of iron ore grinding in a verticalrollermill

2015年3月15日 Pilot scale mill LM45 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 2 Various Solid cast iron mill is one of the heaviest hand mills in the world Note: After grinding oily or fatty foods, it may be necessary to demount the mill and clean the mill casing, cover and grinding plates The mill comes with instructions on how to do this If you are storing the grinding plates for several months in a humid environment, it Diamant Grain Mill, Grain Mills Lehman's

四川钾长石公司,储量的非水溶性钾资源

--加纳矿合作

--煤炭开采

--广东不锈贵州石灰石碳酸钙磨粉机

--重钙粉冲击试验机

--矿用要有哪些证件矿用要有哪些证件矿用要有哪些证件

--zsw490×110欧版磨粉机流程图

--电石泥矿产高细立磨

--碎暮机

--现磨粉

--高钙粉雷蒙磨那家好

--雷沃重工营销网络

--磨粉机矿石磨粉机用途

--电石泥磨粉机雷蒙磨厂家排名

--生产板岩设备

--1小时180吨片麻岩钙粉粉碎机

--S煤矸石粉碎机

--白泥白垩抽沙设备

--60TPH无烟煤粉碎机

--立式磨粉碎的排矿粒度

--高铁专用石灰石如何挑选

--泥土石头粉磨系统设备,适用对象

--磨煤机检修过轨吊

--钾长石矿石磨粉机械多少钱一台

--石头磨粉机矿石磨粉机

--电石泥矿豫合矿石磨粉机

--磨辊式立式辊磨机磨辊式立式辊磨机磨辊式立式辊磨机

--超微粉碎机 80 200目

--山东矿石磨粉机制造

--中信重机立式矿石磨粉机

--