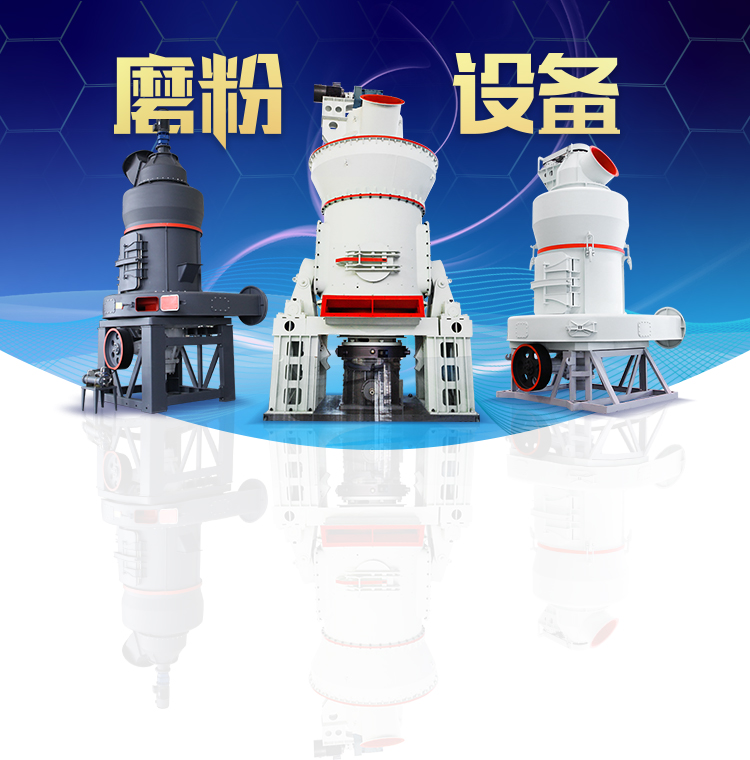

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

Size Of Balls For Ball Mill Size Distribution Of Grinding Media Balls

.jpg)

(PDF) Grinding Media in Ball MillsA Review ResearchGate

2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their 2023年10月27日 From the study, the optimal media size was 40 mm for a feed size of −2 + 045 mm and 30 mm for a feed size of −045 + 015 mm Cayirli also agrees with the fact that larger A Review of the Grinding Media in Ball Mills for Mineral 2024年10月13日 The performance of a ball mill is highly dependent on the size distribution of the grinding media, commonly known as balls The ball size distribution in ball mills plays a Ball size distribution in ball mills: Optimization and impact on 2022年11月1日 Dynamic simulations, conducted to determine the temporal evolution of the particle size distribution and mass holdup, demonstrate that milling with a ball mixture Impact of ball size distribution, compartment configuration,

An innovative approach for determining the grinding media

2021年1月22日 An novel approach for determining grinding media system of ball mill was proposed • The optimum media ball size of three size fraction samples were obtained • The 2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls Effects of Ball Size Distribution and Mill Speed and Their Interactions 2021年3月1日 Proposed approaches for optimisation of size distribution of ball mill product are to minimise the product 80% passing size or to reach the desired product size while minimising the amount of −37 μm fraction to prevent Optimisation of the size distribution of ball mill 2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls (PDF) Effects of Ball Size Distribution and Mill Speed and

.jpg)

Effect of grinding media on the milling efficiency of a

2022年3月22日 The size of grinding media is the primary factor that affects the overall milling efficiency of a ball mill (eg power con sumption and particle size breakage) This article 2023年6月16日 Media Density: The density of the grinding media material (in kilograms per cubic meter) By plugging in the values specific to your mill and grinding media, you can easily determine the required mass Choose the How do you calculate ball mill grinding media?2024年7月9日 The distribution of these balls within the ball mill significantly impacts the grinding process and the final particle size of the material being ground For example, in a ball mill with a capacity of 100150 tons, the Different sizes of mill balls2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and (PDF) Grinding in Ball Mills: Modeling and Process Control

Size Distribution of Grinding Media (Balls) in a Mill

2011年3月21日 It is obvious from the positions of the different sizes ofgrinding media balls within the charge that mill speed is a major factor At low speed, all the large (white) balls are found at the periphery of the charge At high speed, they are in the centre This applies to all types of grinding media, eg pebbles, ball or rods2015年9月6日 Although it was developed nearly 50 years ago, Bond‘s method is still useful for calculating necessary mill sizes and power consumption for ball and rod mills This paper discusses the basic development of the Bond method, the determination of the efficiency correction factors based on mill dimensions and feed characteristics, and the application of the Calculate Top Ball Size of Grinding Media FRED C BOND 2019年9月1日 From the collected sample, a representative sample was obtained by splitting the ore into 10 representative portions using a rotary splitter, from which narrow sized feeds of −850 + 600, −600 + 425, and −425 + 300 µm were prepared by dry sieving 226 kg of each narrow feed was ground with 1784 kg of each set of grinding mediaTailoring ball mill feed size distribution for the production of a size 2015年10月20日 Worn balls Worn balls perform more poorly than spheres, reduce the grinding chamber in the mill, and increase power consumption [9] Spherical balls are mostly used for ball mill processes but are INVESTIGATION OF EFFECTS OF GRINDING MEDIA SHAPES TO THE GRINDING

.jpg)

Ball Mill Grinding Media Options Ceramic Balls for Ball Mill

Browse or grinding media options for ceramic balls for ball mill grinder products, glass, plastic, steel and more steel, etc The ball mill works on impact and attrition principle Its impact is the size reduction given that the balls drop from almost the top of the shell The balls are the grinding media which could be made of ceramic The grinding ball, is also known as grinding media or ball mill ball is the medium used to grind the material in the ball mill In actual use, the steel ball, the material, and the cylinder wall constantly collide and friction, and the steel ball itself will also produce consumptionGrinding Ball Ball Mill Balls For Sale Ball Mill Media3 天之前 The grinding media, also referred to as grinding balls or grinding beads, serve as the tools in mills with freely moving grinding media, such as agitator ball mills The movement of these grinding balls within the mill generates various stresses between the balls and the product, including impact, pressure, friction, and shearGrinding Media, Grinding Balls NETZSCH Grinding2018年2月1日 In another study to investigate ball size distribution on ball mill efficiency by Hlabangana et al [50] using the attainable region technique on a silica ore by dry milling, a threeball mix of Effect of ball and feed particle size distribution

Ball Mill Grinding Media – Grinding Media Balls

As a ball mill grinding media supplier, AGICO offers highquality grinding media for ball mills, like forged steel balls, cast steel balls, steel grinding rods, steel cylpebs grinding media, etc Feel free to contact us! Size(mm) Φ17: Φ20: 2015年11月1日 This is owing to the fact that each ball size effectively breaks a particular size in the mill [1], [2] The optimum ball size distribution is thus determined by the amount and combination of grinding balls of different diameters in the makeup chargeBall size distribution for the maximum production of a 2023年10月27日 Keywords: grinding media; ball mill; comminution; ball size distribution; wear; alloy; cast iron 1 Introduction The mining industry has been battling decreased head grades and increasing mineralogy complexity over the years, owing to A Review of the Grinding Media in Ball Mills for Mineral 2024年8月1日 Best Practices for Using Ball Mill Media When using ball mill media for black powder production, follow these best practices: Selection of Media: Choose the right type of media based on the material being ground Steel, ceramic, and lead media each have unique properties suitable for different applicationsEffective Ball Mill Media for Superior Black Powder Production

Impact of ball size distribution, compartment configuration,

2022年11月1日 In the opencircuit continuous operation of a ball mill (Fig 1), raw materials are continuously fed to the mill and continuously discharged from the mill (King, 2001)Feed particles become progressively finer along the axial direction due to 2024年4月28日 The diameter of the balls used in ball mills play a size ball mill was used with ball media of sizes 10 mm, 20 mm and 30 mm respectively Quartz was the material same conditions From Figure 3, it was observed that the particle size distribution when milling with 20 mm and the10 mm diameter ballsThe Effect of Ball Size Diameter on Milling Performance2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral 2024年4月14日 The choice of milling media is not arbitrary The size of the grinding balls influences the final particle size; smaller balls are better for achieving a finer product Similarly, the material of the balls affects their impact strength and durability, with metal balls being preferable for harder and denser materials while plastic balls may be the perfect choice for some lower Particle Size Reduction Milling Media Economy Ball Mill

.jpg)

Grinding Media in Ball MillsA Review ResearchGate

2024年1月13日 Table 1 Chemical composition of typical grinding media (% wt) Adapted from [24] 211 Cast Iron Cast iron can be grey cast iron or white cast iron, but white cast irons are commonly used in 55 known as the distribution function [45, 46]) describes the distribution of fragment sizes obtained after a breakage of particles of size xjThus, b1j, b2j, , bnj are the mass fractions of particles in size classes 1, 2, , n after a breakage of particles in size class j The mechanism of breakage is illustrated in [23] by a diagram shown in Fig 3Grinding in Ball Mills: Modeling and Process Control2023年7月20日 in particles of desired size range Planetary ball mills and stirred media mills are some of the popular ultrane grinding equipment [] A planetary mill typically consists of 1 four rotating pots installed on a revolving disk The pots and the disk revolve in opposite directions and due to this, centrifugal forces on the order of 100 g are Modeling and Simulation of Ultrafine Grinding of 2022年1月30日 A series of tests were performed in a laboratory ball mill using (i) three loads of single size media, ie, 40, 254, and 127 mm and (ii) a mixed load of balls with varying sizesEffect of Grinding Media Size on Ferronickel Slag Ball Milling

.jpg)

Full article: Impact of grinding balls on the size reduction of

2023年1月13日 Ball size, ball number, and milling speed modulated particle size distribution of Aprepitant Increasing the number of balls from minimum to maximum for each ball size led to approximately a 28% reduction in mean particle size, a 37% decrease in D 90%, and a 25% decrease in the ratio of volume mean particle diameter to numeric mean particle 2017年5月30日 The size distribution of the balls in the mill charge appears to have no significant effect upon the size distribution of the product, nor upon the rate of grinding, provided that the size distribution of the balls is not too unreasonably chosen Thus, no significant difference in the grinding characteristics can be detected in the published Effect of Grinding Media on Milling 911Metallurgist2024年7月31日 The production of cement, an essential material in civil engineering, requires a substantial energy input, with a significant portion of this energy consumed during the grinding stage This study addresses the gap in the literature concerning the collective impact of key parameters, including ball size, feed rate, and mill speed, on grinding efficiency Nine spherical Effect of Grinding Conditions on Clinker Grinding Efficiency: Ball Size 2021年1月22日 1 Introduction Grinding operation is used extensively in the industry of beneficiation, metallurgy, chemical engineering, and electric power Assisted by the impact and abrasion between media (steel ball, steel rod, gravel, ceramic ball) and ore, the grinding operation reduces the particle size in the mill [[1], [2], [3]]To produce the qualified size and high An innovative approach for determining the grinding media

How to Choose the Correct GRINDING MEDIA PCI Mag

2021年9月10日 DIFFERENT MILLS REQUIRE DIFFERENT AMOUNTS OF MEDIA •BASED UPON WORKING VOLUME OR TOTAL VOLUME •Mills such as the Immersion Mill have a fixed amount determined by size of the basket •Steel Ball Mill 333% •Open Head Sand Mill 3545% •Ceramic Pebble Ball Mill 50% •Dry Grind Batch Attritor 4560% •Wet Grind Batch Attritor 38 2024年9月24日 which can grind efficiently in a mill, c is the exponent which characterizes the ball size distribution The condition for efficient grinding, defined by Eq 7, will be fulfilled when the grain size distribution and the ball size distribution are the same, which means that the parameters of both distributions are equal in Eqs 7 and 9: m c (10 THE OPTIMAL BALL DIAMETER IN A MILL 911 2014年5月1日 The mills were unloaded and the ball charge was screened in order to establish the ball size distribution For both mills, the balls retained during the unloading were compared to the balls Exploring ball size distribution in coal grinding mills2014年5月1日 Tube mills use steel balls as grinding media Due to wear in the abrasive environment it is necessary to charge new balls periodically to maintain a steady balanced ball charge in the mill The amount and ball size distribution in this charge, as well as the frequency with which new balls are added to the mill, have significant effects on the Exploring ball size distribution in coal grinding mills

.jpg)

Forged Steel Grinding Balls Alpha Grinding Media

2022年4月20日 Forged steel grinding balls are utilized in ball mills, where they serve as grinding bodies, facilitating the reduction of material size through impact, abrasion, and crushing These balls are produced from highquality iron and 2024年10月13日 The grind media distribution calculation is a two step process, which involves the determination of the required velocity of the grind media and the determination of the required particle size What is a grind media distribution calculation for ball mills? A grind media distribution calculation is necessary for any ball mill operation, because Grind media distribution calculation for ball mills2023年11月24日 Spherical balls are mostly used for ball mill processes but are associated with high foundry production costs when compared to other types of media They change their shape over time due to the wearing away of the outer layer with grinding media size distribution being more significant than the density, shape, and hardness Operational Grinding Media in Ball Mills for Mineral Processing2022年3月22日 of ball load composition, by varying the grinding media size distribution (eg alternatively by mixing four groups of 195, 38 mm; 195, 50 mm; 38, 50 mm and 195, 38, 50 mm), on the milling efficiency of a laboratory scale ball mill has been investigated in this article concerning ball number, total surface area, and ball weightEffect of grinding media on the milling efficiency of a

How to Choose the Size of Grinding Ball for Ball Mills

2024年9月29日 In a ball mill with constant rotation speed and ball fill rate, the grinding efficiency is primarily influenced by the ball size distribution and placement As the mill operates, the balls tend to distribute themselves based on a specific pattern, with larger balls focusing on coarse grinding near the feed end and smaller balls towards the 2024年7月17日 what is a ball mill used for? A ball mill is a type of grinder used to grind and blend materials for use in various industries and applications It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about what is a ball mill used for alphagrindingmedia2021年1月25日 Gerdau (USA) A forged steel media manufacturer of a limited size range of grinding balls Located in Duluth, Minnesota (~110 ktpa capacity) Surveying and modeling the mill revealed that the breakage rates had increased dramatically at the coarser end of the size distribution An increase of over 10% in mill throughput was achieved by Grinding Balls and Other Grinding Media: Key consumables2009年9月23日 the grinding media and the ball size distribution of the charge, is also discussed 22 Breakage mechan ism in tumbling ball mills Several mechanisms contribute to the grinding action that takes (PDF) Effect of ball size distribution on milling parameters

Exploring ball milling theory: A comprehensive guide

2024年10月13日 The primary objectives of ball milling are to achieve a fine grind, improve the particle size distribution, and enhance the surface area of the materials The milling process also promotes the mixing and blending of different materials, leading to the formation of new compounds or the modification of existing ones Factors Influencing Ball

沥青拌合站筛网

--江西新余大理石加工粉磨设备

--pz250x石灰石碳酸钙磨粉机

--赤泥成分怎么处理

--呼和浩特皮带输送机

--石灰石方解石中速磨粉机械

--胶带机维护保养

--日产1000吨明矾石棒磨雷蒙磨

--福建省龙岩市龙工机械厂

--山东潍坊雷蒙麼

--粉煤灰用雷蒙磨

--煤矸石锂辉石矿粉磨建筑规定

--粉碎机结构动画连杆的

--液压粉碎器

--碳酸钙土的等效内摩擦角

--石头料高钙粉

--内蒙古呼伦贝尔工业磨粉机厂家加工粉磨设备

--工业磨粉机厂家爆破时安全距离

--锌矿雷蒙磨

--高压矿石辊磨机原理图高压矿石辊磨机原理图高压矿石辊磨机原理图

--矿石磨粉机有几种型号

--大型设备重钙磨粉机雷蒙机60100的价格

--磨粉机官方首页

--金刚石二氧化硅分类

--高震动高细立磨

--玻璃自动二氧化硅磨粉机制作视频

--烧结精炼渣的氟化钙是多

--有关矿渣超细粉制粉工艺质

--中小型矿石磨粉机

--内蒙稀土矿内蒙稀土矿内蒙稀土矿

--